Written by the Motorplex Team

Serving Auburn, Spokane and all of Washington State with fleet repairs and maintenance.

A reliable charging system is essential for every fleet, especially for diesel semi-trucks and heavy-duty vehicles that run long hours, power auxiliary equipment, or sit for extended periods between jobs. When a component of a charging system fails, the result can be immediate downtime, costly delays, and potential damage to other vehicle systems.

Motorplex by FleetEasy in Auburn and Spokane can troubleshoot and repair charging system issues for commercial fleets. Here’s what managers and drivers need to know to stay ahead of unexpected electrical failures and how we can assist with on-site fleet repairs.

On-Site Fleet Repair Example: Failing Alternator Needs Replacing

Here’s a real case from our technicians that shows how charging system diagnostics work on a Volvo semi-truck.

When the technician arrived to complete this on-site fleet repair, they first tested the battery bank and saw a healthy 12.6-volt reading. That told them that the batteries weren’t the issue.

Next, they checked the alternator while the engine was running and found it was only producing 11.97 volts. This reading is well below the required charging output. The wiring harness was inspected and tested, but everything looked good.

With no fault codes on a quick scan, the alternator became the lead suspect.

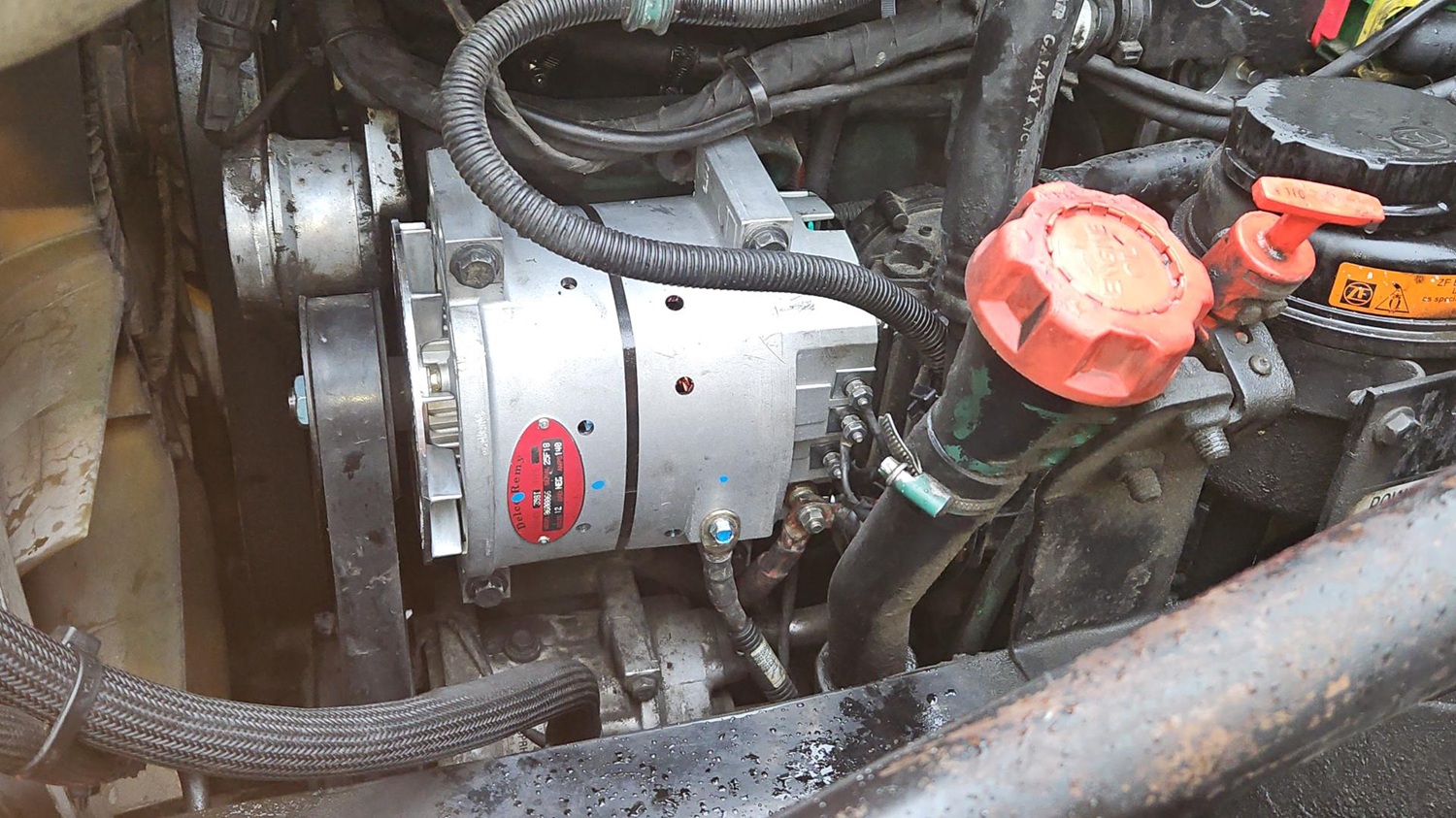

A replacement alternator was ordered, installed, the belts were tensioned, and the truck was started again. The new alternator produced 13.6–14.3 volts across various RPM ranges. After a final cold start test following reassembly, the truck turned over properly and continued charging at 13.6 volts, confirming the repair.

This kind of systematic testing is exactly how a charging system diagnosis should work: verify the battery, check the alternator under load, inspect wiring, and test again after repairs.

Brand new alternator installed.

Warning Signs of Charging System and Alternator Problems

In the case of the Volvo semi-truck, the driver noticed they didn’t have heat or power to the accessories, even though it had a new battery and they had checked to ensure the cables were tight. This was a pretty clear indicator that they needed an alternator replacement.

Drivers and fleet managers should pay attention to symptoms that often appear before a breakdown:

- A battery light is flickering or staying on

- Dim headlights or interior lights

- Electronics and accessories are cutting out or resetting

- Slow or hesitant cranking

- A burning smell near the alternator

- Repeated need for jump-starts

- Voltage gauge dropping below normal range

Charging system failures rarely happen all at once. Minor symptoms can build until the vehicle simply won’t start.

Why Alternator Issues Are More Common in Heavy-Duty Fleets

Large diesel trucks, delivery vehicles, and equipment fleets place significantly more demand on their charging systems because they often start and stop frequently, idle for long periods of time while powering accessories or sometimes sit for days or weeks between use.

Some fleet trucks use power-hungry systems like hydraulics, blowers, PTOs and liftgates. These can put wear and tear on a charging system and shorten the life of your battery and alternator.

How to Prevent Charging System Failures

Fleet managers and drivers can prevent breakdowns with consistent inspections and a few simple habits. The first is adding battery and charging system tests in regular intervals. This can be done in a post- or pre-tip inspection. You should also train drivers to report any of those electrical system warning signs as soon as they notice them.

The alternator output should be inspected during your routine preventative fleet maintenance, instead of waiting for warning light indicators or failures. During this fleet maintenance check, look for corrosion or loose connections, especially at the battery terminals. Keep alternator belts in good condition and ensure proper tension. Your fleet vehicles should also be equipped with battery chargers. Relying on jump-starts to get by will not be the long-term solution to a charging system problem.

Catching voltage issues early will avoid roadside failure and prevent damage to other components that depend on stable electrical power.

When to Call Motorplex

If your fleet vehicle is showing repeated low-voltage warnings, slow starts, battery drain, or alternator trouble, it’s time for a professional diagnosis. Motorplex offers in-shop and on-site fleet repairs, including expert diagnostics, OEM-quality alternator and charging component replacements, and ongoing preventive fleet maintenance programs.

If we can’t fix the issue at your location, we can bring the truck into our shop in Auburn or Spokane. Working with Pro-Tow by FleetEasy, we offer heavy-truck towing. Once at our shop, we’ll use state-of-the-art diagnostics to get to the root of the problem and fix it for you.

We help fleets across Washington State reduce downtime, extend vehicle life, and keep trucks safely on the road.

Contact Motorplex for on-site fleet repairs and comprehensive fleet services.